|

|

|

Wine, Drinks and Oil Equipment |

| |

|

|

|

| |

|

|

|

|

|

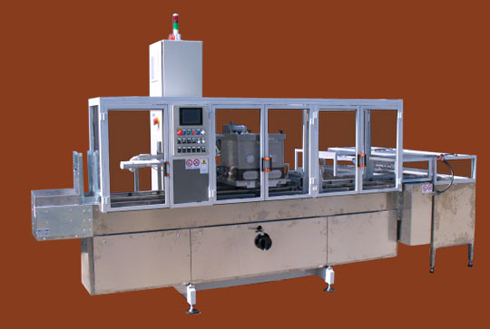

| ONE SHOT DOSING MACHINE DSR |

|

One-Shot Depositor can produce any type of filled articles in just one operation. One-Shot Depositor can produce any type of filled articles in just one operation.

With its high technology level the machine deposit at the same time the chocolate for the shell forming and the cream for the filling.

This process is a cost saving, since it’s a good alternative to the traditional technology in most productive processes.

Both hoppers with the working products are equipped with an independent heating system, this way is possible to deposit at the same time products with very different densities. It can produce also every kind of solid articles, using the chocolate also for the filling.

DSR was designed to be extremely modular, user friendly, easy to clean and quickly ready to a production changeover.

The Depositor can work as a stand alone machine or in a new or existing line. Suitable for small, medium and large productions.

Characteristics

• Speed: 15-20 moulds/minute;

• Simultaneous depositing of different masses;

• Servomotors for the main movements;

• Rotating pistons for depositing easily removable for cleaning;

• Multi-axis movements;

• Moulds automatic feeding belt;

• Double jacket insulated hoppers with own stirrer and vibrating sieve;

• Two different independent heating section for the chocolate and filling temperature regulation;

• Management dedicated Software;

• Man-machine interface through "touch- screen" operator panel;

• Controls managed by dedicated PLC;

• Operation language selection;

• Accurate setting and control of the temperatures;

• Unlimited number of set recipes;

• Modem connection for tele-assistance operations;

• Depositing plate with nozzles easily interchangeable, designed specifically for the different types of moulds.

|

|

| | | | |

|

|

| |

|

|

|

© Arvinoil Pty Ltd reserves the right to change at any time any data and physical features described on this site. |

Reserved Area | |

| | | |

| |

|